TNA Solutions, a global player in the food processing and packaging segments, has been enhancing its food processing portfolio with improved efficiencies and reduced product wastage.

The company has enhanced its confectionery processing portfolio with the launch of the tna mogul ST and tna mogul MX starch-molding solutions, with a capacity of 3500 kg/hr and 6000 kg/hr respectively. This new generation of mogul systems features high-precision depositing technology with better efficiencies and reduced wastage, helping achieve consistent quality products. Other updates include an innovative design of main assemblies for hands-on operations, reduced maintenance, and an improved starch recovery system.

The snack industry in India is experiencing remarkable growth, becoming the third-largest market in Asia over the past four years, with a compound annual growth rate (CAGR) of 10%, as reported by Euromonitor. This rapid expansion presents significant opportunities for food manufacturers looking to tap into this diverse market.

In a conversation with IndiFoodBev Palani Karai, general manager of TNA MENA, talked about the company’s offerings and innovations while Aviraj Phadke, regional sales manager of the India division, discussed the development of the snack-based industry in India.

Phadke, talking about the trends in the Indian market, said the strategic establishment of manufacturing and packaging facilities by snack brands every 500 to 750 kilometers is minimizing logistics costs. “This step is crucial in the snack industry, where products often consist of approximately 80% air and only 20% the actual product. When transportation distances exceed 750 kilometers, profitability tends to diminish, making it essential for large snack manufacturers to maintain a network of localized production facilities across India,” he said.

“Another significant trend is the gradual shift from the unorganized sector to the organized sector,” Karai says. “Despite the presence of numerous large players, a substantial portion of the snack food industry remains unorganized, with traditional snacks often produced at home and sold in local shops. However, there is a noticeable transition towards packaged foods, which is expected to drive growth in packaging and processing lines over the next 5 to 10 years. Consumers are increasingly favoring packaged goods over loose products from shops, indicating a shift in purchasing behavior.”

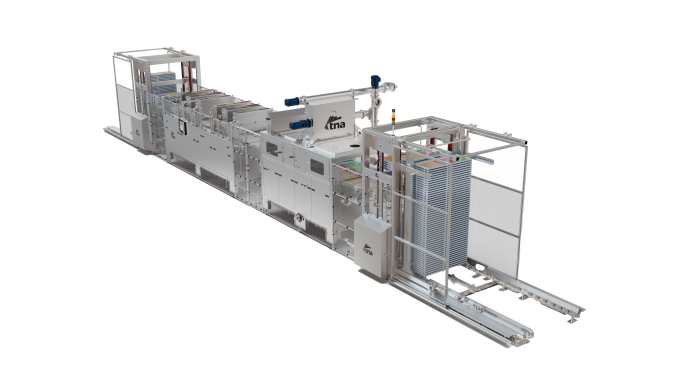

Karai says the company’s overall business is performing well, “mostly because TNA is the only global single-source solutions provider capable of delivering equipment for the entire potato snack production line. This unique capability is especially valuable for smaller and emerging brands, who increasingly rely on us to optimize productivity across their entire production process, as well as, for large organizations that want to ensure standard high-quality solutions to be provided.”

Phadke adds, “Continuing to expand our processing solutions, we have begun our journey into tortilla chip processing with our soon-to-be-launched tortilla chip fryer. User-friendly by design, it minimizes frying oil volume, and its filtration system guarantees the maintenance of high-quality frying oil throughout production. With tortilla chips becoming more popular globally, this processing line is a great addition for snack manufacturers, and TNA can partner with complete solutions, from processing to seasoning, distribution, and packaging.

Additionally, there is a growing demand for global snack products such as tortilla chips, fruit chips, vacuum chips, and kettle-style chips, all of which are gaining traction in the Indian market. A further shift is aligned with the broader global trend towards health and wellness.

Phadke elaborates on the subject, saying India is a cost-sensitive market, but the company’s on-ground experience shows that brands value a partner who can provide high performance, production efficiency, and, most importantly, reliability.

“We see significant potential for growth in our processing capabilities, particularly in full lines. This year, we participated in Anuga FoodTec India with a special focus on french fries processing. We see a shift towards greater automation in production lines, which enhances reliability and reduces the likelihood of manual errors. Although labor costs in India are lower compared to other countries, the cost of errors in manual processes can still be substantial. Hence, adopting automation is a crucial trend for improving accuracy and efficiency,” he adds.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now