At the Indusfood Manufacturing show in Delhi-NCR, Pune-based Vibracion highlighted how modern vibratory conveying and screening technologies are transforming food and post-harvest processing operations.

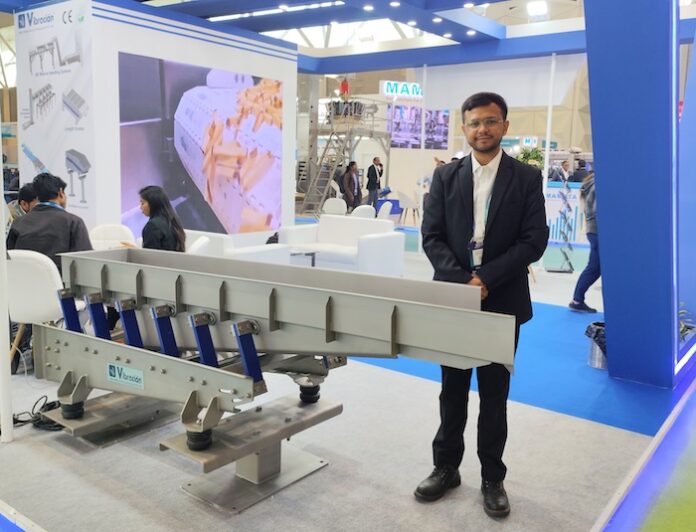

Dhruvil Shah, sales manager, Shri Vibracion Technologies, shared insights into the company’s core focus areas, application strengths, and the growing shift among Indian processors from conventional conveying methods to vibration-based systems.

Shah said the company was founded with a clear specialization in vibratory conveying, elevating, and screening solutions. “When we talk about food processing, all the processing lines are connected between different processes, where material or product has to be conveyed from one stage to another,” Shah explained. “This is where the critical role of Vibracion comes into the picture. We are providing efficient conveying solutions.”

Beyond basic conveying, the company’s portfolio extends to applications such as dewatering, deoiling, product spreading for IQF (individually quick frozen) lines, and complete material-handling systems leading up to packaging. According to Shah, these systems are integral to ensuring smooth, hygienic, and efficient product flow across food plants.

The company showcased demo models of the HDFlex system, vibratory spiral elevators, and screening solutions at the show. The HDFlex system, in particular, drew attention as an efficient pre-packaging conveying and distribution solution designed to feed multiple packaging lines with controlled and uniform product flow.

At Indusfood Manufacturing, Vibracion primarily targeted processors from the namkeen and snacks segment, frozen food processors, as well as rice and millets players. These sectors, Shah noted, increasingly require gentle and reliable conveying solutions due to product sensitivity and high-throughput demands.

One of the key advantages of vibratory conveying is its ability to handle delicate and flavored products without segregation or quality loss. Shah emphasized that precise control of vibration is essential. “Maintaining the right vibration is an important part of conveying, as improper vibration can damage or segregate the product mix,” he explained, adding that the company’s systems are equipped with controllers that allow operators to manage vibration frequency for gentle handling.

Products such as flavoured namkeens, seasonings, masalas, extruded snacks, and even flavoured cashews fall under the delicate category. “If gentle conveying is not maintained, flavour loss can occur, which will directly impact product quality at the customer end,” Shah noted.

Customization and seamless integration

Customization is central to Vibracion’s approach. Each system is engineered based on plant layout, capacity, hygiene requirements, and specific product characteristics. “Our product is about connecting the dots in the processing line,” Shah said. “So it is totally customized based on the plant layout, capacity, product characteristics, and many other technical parameters.”

With automation and real-time communication between conveying systems and packaging machines, consistent product availability and controlled feed rates are maintained. “Our systems come with automation, where we receive continuous signals from the packaging machines regarding material requirements,” Shah explained.

Market presence

Vibracion has a strong footprint across India, with more than 800–900 systems installed across sectors such as namkeen, chips, spices, frozen fries, frozen vegetables, and fruits. The company has a wide geographic presence across Gujarat, Maharashtra, Uttar Pradesh, other parts of North India, Tamil Nadu, and the Bengaluru region.

Speaking about the exhibition, Shah said they received curious walk-ins with several questions. “Visitors were happy to know that we can do something with vibration that they had not thought of earlier.”

The company recently consolidated its manufacturing operations into a new, larger facility at Chakan, Pune. The new plant is nearly double the size of the earlier unit and is equipped with upgraded infrastructure to support quality manufacturing and faster deliveries.

“We have recently inaugurated the new facility at Pune, Chakan, which is nearly twice the size of our earlier unit,” Shah said. “It is equipped with all the necessary infrastructure, which is helping us deliver quality machines and helping processors improve overall plant efficiency.”

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now