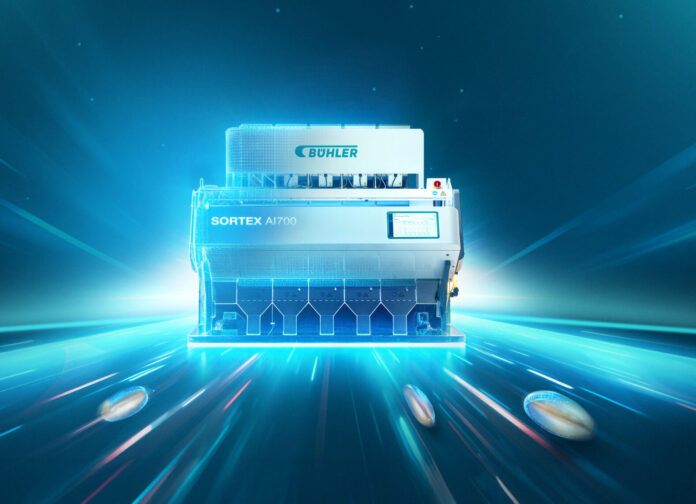

Swiss technology group Bühler has launched the Sortex AI700 optical sorter in London, transforming impurity detection in food processing. Its first application specializes in removing gluten-containing grains from oats, a critical step in ensuring gluten-free product integrity. Utilizing deep learning, the new machine achieves the highest defect removal to date, enabling food processors to significantly improve product quality while increasing yield.

More than just technological advancements, deep learning and Artificial Intelligence (AI) are fundamentally changing the landscape of optical sorting. Bühler ’s latest innovation, the Sortex AI700, introduces a new approach to identifying and removing impurities, leading to improved defect detection and enhanced profitability for food processors.

Melvyn Penna, a key figure in optical sorting advancements and the product manager of the new Sortex AI700, describes the sorter as his “most exciting project yet.” He explains the core technology, “In the past, our machine learning systems, like those in the Sortex SpectraVision series, relied on engineer setup and tracking algorithms to improve upon those initial parameters. Now, with the AI700, we’re implementing deep learning, where the machine employs Convolutional Neural Networks (CNN) to identify defects. Trained with millions of labelled images, the algorithm develops a comprehensive understanding of acceptable and rejectable material, utilizing color, shape, and texture.”

The direct benefits for food processors are significant. “With the AI700, we’ve observed improved defect removal efficiencies while simultaneously reducing the rejection of good products. This means processors can extract more usable products from the same input, leading to less waste and greater revenue. Real-world analysis indicates that a 5-10% improvement in reject concentration over a year can translate to a revenue increase of hundreds of thousands of dollars. The yield lost or gained becomes a key catalyst in the success of a business,” says Penna.

Several future trends in food processing underscore the necessity of this development. These include rising raw material costs, the increasing prevalence of defects due to climate change, stricter market regulations, and elevated consumer quality standards.

Protecting product integrity in gluten-free processing

A critical initial application of the Sortex AI700 is in allergen detection for oats. “We’ve achieved unprecedented levels of removal for barley, wheat, and rye from oats,” says Penna. “This is crucial because oats are gluten-free, while the others are allergenic. Traditional sorters, while meeting regulatory standards, cannot match the gluten removal precision of the AI700.”

Looking ahead, Sortex AI700 will be trained on other commodities. For now, the initial launch is exclusively for oats. Sortex AI700 is an example of Bühler ’s commitment to innovation and food safety, demonstrating how AI can be used for the benefit of processors and consumers.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now