UK-based BMT (Blow Moulding Technologies) will showcase its advanced lab-based solutions, Blowscan and Thermoscan, at drinktec 2025 Munich. These tools are designed to support improvements in PET bottle performance, reduce waste, and accelerate development cycles.

“At BMT, we engineer the virtual world for real-world environmental impact. By making sustainability achievable, we are helping brands and manufacturers optimize material use, reduce waste, and improve bottle performance,” comments Yannis Salomeia, BMT CEO and co-founder.

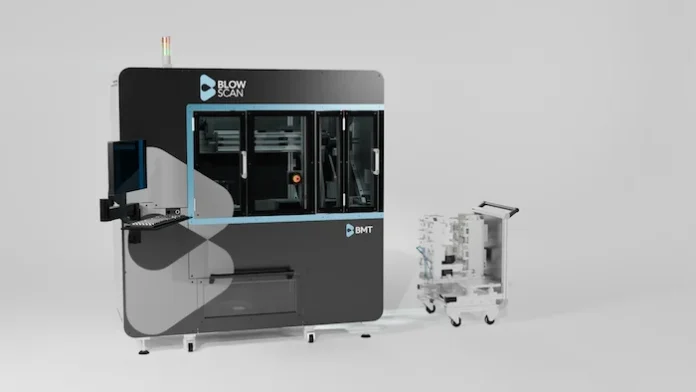

Blowscan is a lab-based, single-cavity stretch blow molding (SBM) platform that provides detailed, data-driven insights into material performance, preform quality, and bottle development without interrupting production lines. As the industry increasingly uses recycled PET (rPET) and other sustainable materials, understanding material behavior in SBM is critical to ensure consistent bottle performance.

Blowscan supports both free-blow and mold-blow modes. In free-blow mode, materials are stretched without mold constraints, ideal for benchmarking new or recycled materials. In the mold-blow mode, it enables rapid prototyping and geometry validation, improving design iteration and increasing material validation rates by up to 20%.

The system uses a batch-fed preform setup without conveyors or hoppers and includes infrared heating to closely simulate industrial conditions. It records essential data, including preform temperature, inflation pressure, and blow geometry, supporting robust analysis across materials and machine setups.

“As brands push for lighter, more complex bottles, even small changes can create processing issues. Blowscan helps de-risk early-stage development with quantifiable insights, while supporting site-specific process optimization,” comments Josh Turner, head of materials characterisation at BMT.

Thermoscan, also on display at drinktec, is a thermal imaging system that helps manage the transition from virgin PET (vPET) to rPET. Recycled materials often exhibit greater thermal variability, affecting bottle consistency and quality.

Thermoscan captures detailed temperature profiles of preforms and bottles. By referencing the temperature data from a successful vPET run, manufacturers can establish starting conditions for rPET and fine-tune heating setups, reducing reliance on guesswork and improving process stability.

Thermoscan supports faster setup times, improves quality consistency, and reduces process variability. It helps benchmark thermal behavior across materials and equipment, cutting profiling time by up to 30%, and enabling faster, data-driven decision-making.

Visitors can also learn about the BMT Way, a structured workflow that combines data, virtual simulation, and technical expertise to guide bottle development from concept to production.

“It begins by capturing how materials behave in the real world, using tools like Thermoscan and Blowscan to gather high-resolution thermal and process data across every stage, from preform to bottle,” explains BMT’s project lead, Jude Cameron. “This data replaces assumptions with measurable, repeatable insights. The information is then translated into virtual models to simulate forming and performance, enabling faster, more informed design iteration.”

“We’re looking forward to connecting with industry partners and sharing insights into the latest innovations in PET packaging, helping clients de-risk development, improve efficiency, and achieve their sustainability goals,” concludes David McKelvey, head of strategic partnerships and innovation.

BMT will be present at Hall C6, Stand 531, 15 to 19 September 2025, drinktec Munich.

(IPP Group’s Shardul Sharma will be present at drinktec Munich from 15 to 19 September 2025 and drinktec Mumbai from 13-15 November 2025 to cover the events. Watch out for drinktec reviews on IndiFoodbev & Packaging South Asia)

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now