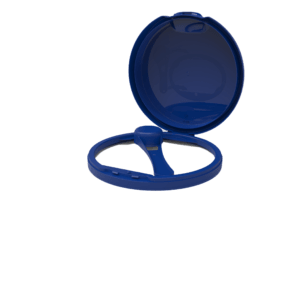

Aptar has launched a new closure for infant formula, NEO. NEO is a tamper-evident closure that features a customizable in-molded scoop for precise and specific dosage. This inventive closure strives to meet the needs of consumers and fulfill their desires for safer, cleaner and more functional products while keeping the infant formula protected and the brand reputation intact.

Synonymous with safety

Safety is key for infant formula, which is why NEO is said to be manufactured in a safe production environment called High Care. This protected area shields the manufacturing process, and enhances safety and hygiene measures to the highest level, to keep products free of any contamination. This innovative industrial environment was explicitly designed to take into account the constraints, risks, and regulations around the packing of sensitive milk formula powder.

Filling line efficiency

According to the press statement, while designing NEO, every aspect was considered to better protect the product inside from external contaminants, a major concern for infant nutrition producers. This innovative closure integrates a flex-band that, although firm, molds itself to fit a variety of containers. The flex-band was designed to guard and protect the infant formula from insects and has been validated by several independent laboratories. Its low application force is suitable for a mechanical or manual application, and the centering mechanism helps to center the closure onto the can easily.

A tamper-evident closure with enhanced consumer experience

NEO was inspired by all those who contribute to an infant’s well-being. Aptar completed numerous studies to understand better the consumer journey, pain points, and the intimate relationships between the package and the user. As a result, NEO was designed to be handled with just one hand, thanks to its ergonomic shape and robust hinge. Upon opening the closure, the consumer will see that the customized scoop is not touching the infant formula, promoting less contamination.

NEO was inspired by all those who contribute to an infant’s well-being. Aptar completed numerous studies to understand better the consumer journey, pain points, and the intimate relationships between the package and the user. As a result, NEO was designed to be handled with just one hand, thanks to its ergonomic shape and robust hinge. Upon opening the closure, the consumer will see that the customized scoop is not touching the infant formula, promoting less contamination.

With one hand, consumers can unlock, use, and replace the scoop to the holder, keeping feeding time clean and easy. Once finished, the lid can be easily resealed by pressing the press-to-close area. The audible click gives consumers peace-of-mind that the container is closed, and the infant formula is protected.

Fully customizable

NEO comes in two diameters – 99 mm and 127 mm – which can be sealed onto all standard infant formula containers, whether metal or composite. NEO is also able to mold itself to fit within a brand’s image and allows companies to choose between three different manufacturing finishes: embossed, in-mold labeling, or bi-injection molding.

Peace of mind

According to Aptar, aspects of safety and convenience were taken into consideration when designing NEO. This closure fulfills the needs of both brands and consumers, providing differentiation, precision, protection, and convenience for all.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now