Swiss technology company Bühler Group has integrated NapaRoast’s pasteurization and roasting technology. With the addition of the NapaRoast steam vacuum pasteurization technology to its broad portfolio, Bühler says it has strengthened its market position in the nuts processing industry to cater even better to trends such as healthy snacking, regulatory compliance, and sustainable practices.

“The integration of NapaRoast puts us in the unique position to be a one-stop shop for our customers. The best-in-class pasteurization process guarantees food safety and traceability, and, in combination with our proven technologies for nuts processing, added efficiency. With the integration of the NapaRoast solution into our portfolio, we look forward to sharing the benefits of this technology and serving the NapaRoast customer base – not just for nuts, but for many of the food processing solutions Bühler offers as well,” says Cathrin Flühler, head of market segment Nuts at Bühler.

The global nut market is growing at an annual rate of up to 7%. The popularity and reputation of tree nuts and ground nuts as healthy snacks due to their high levels of protein, fiber, and antioxidants is growing steadily. With this developing worldwide demand comes an increased focus on food safety. NapaRoast’s steam-vacuum pasteurization process provides the best answer to the stringent microbial contamination requirements that processors are facing today.

“Our pasteurization process offers a high pathogen reduction of >5 log in nuts, seeds, and all low moisture foods. During our process steam is used to raise the surface temperature of the product to kill pathogens effectively,” explains Cameon Ivarsson, co-founder of NapaRoast. By pasteurizing with saturated steam, the products can be treated effectively at lower temperatures in a partial vacuum. The high efficiency of saturated steam does not require a drying step thus protecting the quality, texture, color, and flavor of the product.

The missing piece to the puzzle

“We already covered the most important steps such as transport, sorting, storage, roasting, and grinding in our portfolio. When it came to the pasteurization process, however, we had to rely on solutions from suppliers. Now, our customers can get all the important technologies along the value chain from Bühler, which creates valuable synergies for everyone involved. This collaboration is a perfect match between two companies with the same values such as quality, ingenuity, and creating value for customers and consumers,” says Cathrin Flühler.

Cameon Ivarsson adds, “With Bühler, there is a huge opportunity to multiply the impact of our pasteurization technologies across the globe. Their large customer base paired with decades of experience in plant and process engineering will get the most out of the technology. We could not be more excited about the future for nuts processing.”

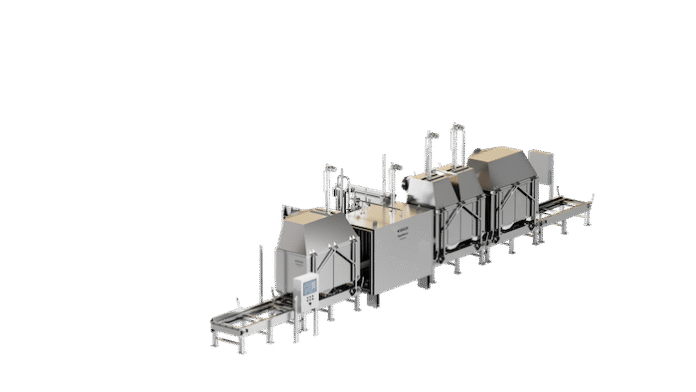

The NapaRoast pasteurization technology is installed in over 40 processing plants around the world, mainly in the United States, Europe, and Africa. Pasteurization and roasting lines are offered in throughputs ranging from 1 ton per hour to 6 tons per hour. Because of the unique design of the process where the product is treated in bulk bins, there is no breakage, dust, and waste, and down time for product changeover is minimized. Its flexibility allows for the processing of whole pieces, chopped ingredients or powders as well.

A unique playground for nuts processors

To showcase its position in nuts processing and to give customers the unique opportunity to test and train along the value chain, Bühler has upgraded its Flavor Creation Research and Training Center processing in Uzwil, Switzerland. “Of course, the pasteurization step is integrated into our state-of-the-art facility for our customers to get first-hand experience of the technology. We are excited to open our center in August this year for trials and to invite them to the first exclusive training session on November 4 and 5,” says Cathrin Flühler.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now