Leybold presents its innovative vacuum portfolio at the international trade fair CFIA – Carrefour des fournisseurs de l’industrie agroalimentaire in Rennes Parc Expo – Rennes Airport from June 9th – 11th 2021 in hall 5, booth B7. The Novadry vacuum pump series will be the focus of the presentation. The completely newly developed, oil-free screw vacuum pump ensures significantly greater safety and efficiency in food and packaging processes.

Vacuum as a key technology

The demands placed by manufacturers and consumers on the quality, shelf life and resource efficiency of food and packaging processes are constantly increasing. This applies even more to such perishable products such as meat or fish. Vacuum is considered as an enabling technology, contributing significantly to optimizing these processes. Therefore, Leybold developed the innovative Novadry, a new 100% oil-free, air-cooled pump, which will be presented at the CFIA.

No oil, less effort

“Many users in meat processing and packaging cannot actually tolerate vacuum pumps emitting oil,” stresses product manager Niels Gorrebeeck. Novadry prevents such contaminations. That is why Leybold designed a 100% dry pump following hygienic criteria. This increases safety in applications such as tumbling, filling, vacuum packaging and thermoforming. An additional advantage of oil-free vacuum pumps is the lower cost of ownership, as less maintenance and spare part changes are required.

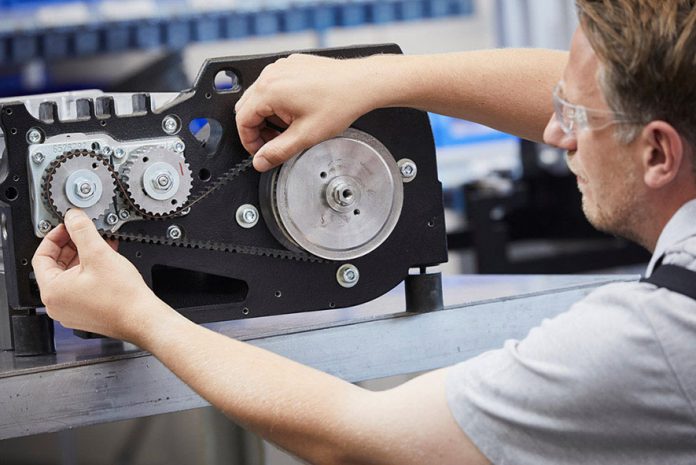

In addition to the oil-free screw principle, Leybold has transferred proven components and principles from other vacuum pump series to the Novadry, including the bearing structure and the belt drive, which synchronizes the rotors.

Air cooling reduces total cost of ownership

Normally, dry pumps are water-cooled, but the NOVADRY is air-cooled. This reduces operating costs by simplifying the installation and commissioning. “The total life cycle operational costs of the Novadry are lower than for oil-sealed vacuum pumps, this was a key driver during the pump development,” explains David Perrin, sales manager Leybold France.

Broad range of applications

The new pump also stands out due to its long uptime and robustness. Pumps can potentially lose their end-pressure or reduce pumping-speed due to wear of the inner coating.The Novadry, however, achieves its performance over the entire pressure range and life cycle. This makes it ideal for simple applications, which emit low amounts of humidity, such as packaging of cold products. Moreover, the pump is also perfectly suited for more demanding processes with large amounts of water vapour, for example when hot meals with temperatures of up to 95°C have to be quickly cooled down by evaporative cooling. “In addition to the air/steam mixture coming from the process, the Novadry screw vacuum pump can also handle the anticipated contamination inside the gas flow very well. These are for example organic acids, spices, vinegar or other residues,” summarizes Pierre Lantheaume, Business Development manager Food & Packaging at Leybold.

Proven in real life

The Novadry has successfully passed many qualifying field endurance tests in a wide range of food applications – tumbling, tray sealing and thermoforming. In all applications, it shows very good performance, the users reached fastest cycle times and low final pressure. The new pump rates well on less noise, robustness and low life time costs.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now