Tetra Pak has taken another step forwards in sustainable packaging by expanding its innovative paper-based barrier technology to high-speed Tetra Pak A3/Speed filling lines, with Maeil Dairies becoming the first producer globally to implement the solution for its soy milk.

This milestone aligns with a broader shift across the food and beverage industry, where producers are accelerating the transition towards low-carbon, renewable packaging materials, the company said.

Developed to replace the aluminium foil layer used in aseptic cartons, the new paper-based barrier maintains comparable levels of food protection and shelf life. When combined with plant-based polymers derived from sugarcane, the Tetra Brik Aseptic 200 Slim carton used with Maeil Soy Milk 99.9 product in South Korea achieved 87% renewable content and delivered a 26% reduction in package carbon footprint, as verified by the Carbon Trust.

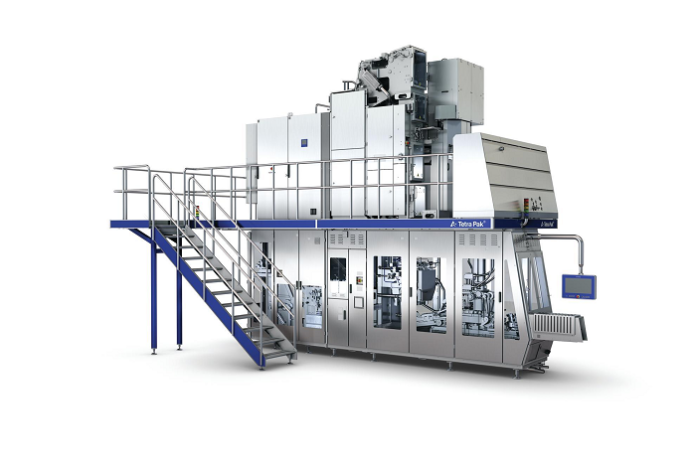

A key milestone of this launch in Asia is that Maeil Dairies is the first producer globally to implement packaging material with the new paper-based barrier on a Tetra Pak A3/Speed filling machine, demonstrating that the technology is now fully compatible with high-speed industrial production.

The Tetra Pak A3/Speed delivers high package outputs of up to 24,000 packages per hour with low operational costs, enabling large-scale deployment while keeping high food safety standards. Moreover, existing Tetra Pak A3/Speed lines can be easily upgraded with a high-frequency induction-heating sealing system, allowing producers to adopt the new packaging material without significant capital investment.

Tatiana Liceti, executive vice president, Packaging Solutions at Tetra Pak said, “Scaling sustainable packaging solutions should go hand in hand with operational efficiency. By bringing our paper-based barrier to high-performing Tetra Pak A3/Speed packaging lines, we are offering beverage producers an opportunity to adopt low-carbon packaging solution based on renewable materials while maintaining food protection and cost-competitiveness.”

The new package for Maeil Soy Milk 99.9 marks the first use of Tetra Pak’s paper-based barrier in the plant-based beverages category. Maeil Dairies, a longstanding innovator in the plant-based beverage market, sees the move as a natural continuation of its sustainability journey.

Inki Lee, chief operating officer at Maeil Dairies commented, “Maeil Dairies has pioneered the domestic low-sugar soy milk segment, establishing a leading position in the market. Introducing new packaging on our Soy Milk 99.9 line reflects our ongoing commitment to innovation and environmental responsibility. Our collaboration with Tetra Pak enables us to drive meaningful, forward-looking change that will benefit consumers and future generations alike.”

The world’s first aseptic beverage carton where the traditional aluminium foil layer was replaced with the innovative Tetra Pak paper-based barrier was launched in 2023, setting a new benchmark for sustainable packaging. This new technology simplifies the packaging material structure, reducing it from three to just two main components. This creates opportunities for recycling infrastructure, with downstream benefits such as maximising the recovery of paper content during the recycling of cartons delivering high-quality fibre and non-fibre fractions. Furthermore, by combining a paper-based barrier with plant-based polymers in the material coatings, the renewable content of the packaging is maximized, resulting in a significant reduction in carbon footprint1.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now