An innovative approach to quality control at Frost Prešov, Slovakia’s largest croissant manufacturer, has been achieved through the installation of three Ishida

IX-EN-2493 X-ray Inspection systems that maximize food safety and help ensure a consistent quality for filled croissants.

Frost Prešov supplies a diverse range of fresh and frozen baked goods to the central European market. A popular product line are croissants containing a variety of fillings such as chocolate, apricot or marmalade which are individually wrapped in 60g pillow packs. Ishida is a world leader in the design, manufacture and installation of complete weighing, packing and inspection solutions for the food industry,

The requirement for a capable quality control solution for these products prompted Frost to approach Ishida for a solution. The company supplied three IX-EN-2943-S

X-ray inspection systems which are working across three lines to inspect approximately 18,000 packs of croissants per hour in a 24/7 operation. In order to handle such high volumes, the X-ray systems incorporate a high-capacity belt system that is capable of speeds up to 75 meters per minute.

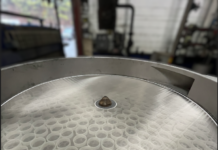

The IX-EN models are performing two different but equally essential quality control checks. Firstly, they carry out vital foreign body detection for companies, with the ability to identify and reject packs containing metal, rubber and other contaminants even at these high inspection speeds.

Equally important to Frost is the missing item feature of the IX-EN range which can detect croissants with missing or defective fillings. This helps to maintain the highest product quality and consistency in order to protect and maintain Frost’s premium brand image.

Before delivery, Ishida’s technical team worked closely with Frost to maximize the effectiveness of the missing item feature. A range of samples was sent to Ishida Europe’s UK headquarters where a series of tests took place to ensure that croissants with out-of-spec fillings were reliably rejected from the line. Central to this capability is Ishida’s unique Genetic Algorithm (GA) image processing feature which optimizes product inspection for greater sensitivity to specific contaminants and quality issues.

“The Ishida X-ray systems are easy to use and to clean, making staff training straightforward,” said Vladimir Varga, Technical Manager at Frost. “Of particular benefit to us is that we don’t have to adjust settings when changing fillings, so this greatly simplifies our production planning.”

The installation marks another milestone in the relationship between the two companies with Frost already using Ishida X-ray inspection systems for other product lines.

“We are really pleased with the level of service we have received from Ishida over the years,” continued Vladimir Varga. “In particular, the company was a huge help in enabling us to solve some technical production issues, working directly with us to ensure that the solution met our exact needs. For that reason, we have a lot of confidence in both the equipment and in Ishida as a brand.”

Following the success of this latest quality control solution, Frost intends to continue to invest in Ishida X-ray equipment for future product lines.

Karel Šmakal, Regional Sales Manager at Ishida commented: “Our long-standing relationship with Frost is a great example of our customer-centered approach. Working together to find the best solution, whatever the specific technical challenge, is very much part of Ishida’s mindset of being a partner rather than just a supplier.”

Established in 2013, Frost Presov produces a wide range of sweet and savoury baked and frozen pastries, sold throughout Slovakia, Poland, Hungary and the Czech Republic.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now