In a significant step towards improving cold chain logistics in Nigeria, a pilot program under the IFC TechEmerge Sustainable Cooling Innovation program initiative is introducing Phase Change Material (PCM) technology to boost efficiency and sustainability in temperature-controlled transportation. Through partnerships with SPAR, a supermarket division of the Artee Group, and local delivery partner IMI, this project aims to preserve perishable goods more effectively in Nigeria’s complex logistics environment.

About the Pilot

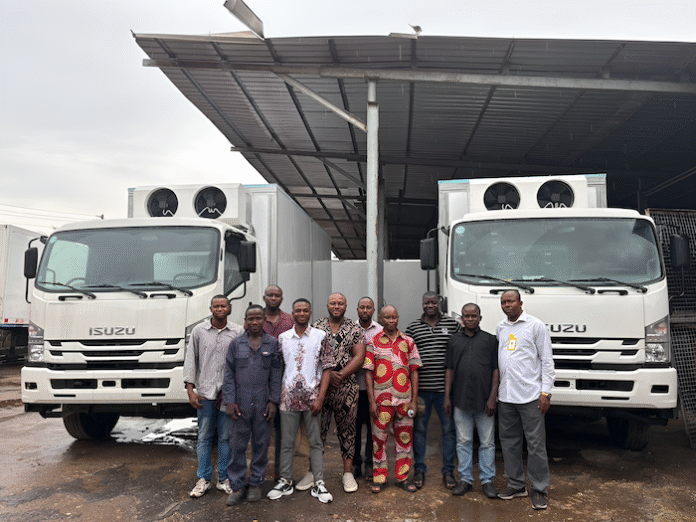

The pilot involves a fleet of four trucks equipped with PCM technology, designed to maintain optimal temperature ranges to ensure product quality during transportation. The fleet includes two 14-ft trucks for chilled goods and two 18-ft dual-chamber trucks capable of sustaining both chilled and frozen temperatures. These trucks use thermoTab active systems with PCM, which takes 6-8 hours to charge at the warehouse and maintains the desired temperature for up to 12 hours, making them suitable for short and long-haul deliveries.

Temperature-controlled logistics (TCL) is crucial for ensuring perishable items are delivered in top quality, yet inefficiencies in TCL systems contribute to substantial food waste globally—estimated at $1.2 trillion annually—and challenge the sustainability of food supply chains. Integrating PCM technology into the fleet is expected to significantly enhance operational efficiency, reducing food waste while promoting environmental sustainability.

Benefits of PCM Technology

- Reduced Carbon Footprint: PCM technology optimizes fuel usage, helping to reduce greenhouse gas emissions in alignment with global climate goals.

- Operational Cost Savings: By maintaining stable temperatures and lowering diesel usage, PCM technology helps reduce logistical costs—a critical advantage in regions like Nigeria, where efficient logistics can support both food security and economic resilience.

- Enhanced Efficiency and Flexibility: The dual-chamber trucks support both chilled and frozen applications, offering greater flexibility in transporting a variety of perishable goods without compromising their integrity.

A Step Towards Sustainable Logistics

This initiative, led by the IFC TechEmerge Sustainable Cooling Innovation program, showcases the potential of advanced PCM technology in creating a more resilient and sustainable cold chain in Nigeria. As consumer demand for fresh, quality-controlled food products continues to grow, such innovations are likely to play a key role in the future of temperature-controlled logistics, ensuring that food reaches consumers safely, efficiently, and with minimal environmental impact.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now