A recent study by Wageningen University and Research (WUR), Netherlands, analyzed the fate of compostable packaging products in a full- scale industrial organic waste treatment plant. The results show that the tested EN13432 certified products break down within a maximum of 22 days. The project was commissioned by the Dutch Ministry of Economic Affairs and Climate Policy (EZK). “The study shows that the tested objects have the same disintegration and degradation rate as regular biowaste or are even faster. We need more research of this kind, conducted by independent and renowned institutions”, says François de Bie, chairman of European Bioplastics (EUBP).

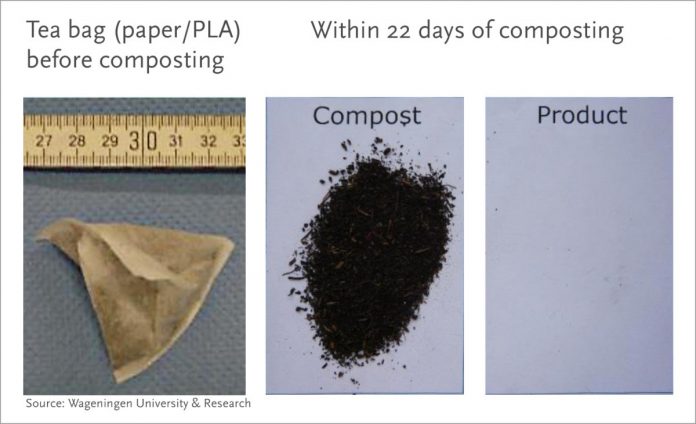

The central aim of the study was to gather more empiric data on the question of whether the disintegration rate of compostable products is sufficient to be compatible with the current organic waste treatment practices. In an industrial organic waste treatment trial, a set of nine different compostable plastic products, consisting of organic waste collection bags, plant pots, tea bags, coffee pads, coffee capsules, and fruit labels, were tested. “We studied how compostable plastics behave in the current Dutch system for the treatment of GFT that is source-separated municipal biowaste and came to the conclusion that compostable products can be processed well with GFT,” says Maarten van der Zee, co-author of the study.

After the first waste treatment cycle of only 11 days, the PLA (bio-based plastic material) plant pot already completely disintegrated. “This is significantly faster than paper and most organic matter. Even the orange peel and banana skin (the reference materials) did not completely disintegrate and needed more time,” de Bie commented on the study. “The PLA tea bag, which is a typical consumer product, also successfully disintegrated within 22 days.”

The study also analyzed the composition of the current visual contamination of conventional plastics in compost, and no compostable plastics were identified amongst the plastics that were found in the compost. “The importance of this result cannot be overstated,” de Bie stresses. “All stakeholders involved in the business of organic recycling, be it waste managers, industry, or legislators, now have the proof that certified compostable plastics deliver.”

European Bioplastics also welcomes the fact that the Dutch Waste Management Association (Vereniging Afvalbedrijven, VA) and Holland Bioplastics (HB), the association representing the Dutch bioplastics industry jointly defined the research questions, which provided the basis for setting-up the project. Besides, VA selected and offered the test facility, while HB contributed the test products. The waste industry and the bioplastics industry must be working together. “Given the upcoming development of the framework for biodegradable plastics included in the European Green Deal, I kindly ask the European Commission to take these research results into account and also to support more similar research projects”, stated de Bie.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now