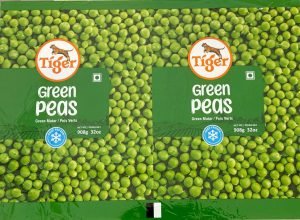

Flexure Print N Pack, a leading flexible packaging printing and converting company based in Ahmedabad, recently accomplished a significant achievement in flexographic printing. The company successfully printed a commercial job for a frozen foods client, achieving a print result of 208 lines per inch (LPI) of resolution.

This feat was achieved on a central impression (CI) flexographic printing press supplied by Echaar Equipments. The job, which comprised eight colors and was reverse printed, showcased Flexure Print N Pack’s printing expertise and technological prowess.

Highlighted the significance of this achievement, Jainam K Shah, director of technology at Flexure Print N Pack, said, “Normally, flexographic printing press room engineers and operators print at lower resolution to control tonal value increments in highlights, mid-tones, and shadow areas and to print vignettes smoothly keeping a trade-off between high-resolution and low to medium resolution printing quality. However, we pushed the boundaries by printing at 208 LPI, demonstrating our engineering expertise and commitment to innovation. This accomplishment is a testament to our dedication to delivering superior quality printing solutions”.

The minimum printed dot during the job was 1.6% and 15 microns in diameter. The job was run on the press at 300 MPM line speed with accurate registration. Process color densities achieved were 1.75, 1.55, 1.30, 1.90 for CMYK inks, respectively. The tonal value increments measured were well under the tolerance of standard values.

Shah emphasized the importance of understanding the intricacies of the flexographic printing process, from high-definition graphic image resolution to anilox roller and plate resolutions and translating them onto the substrate accurately. Printing at higher LPI not only enhances image detail and sharpness but also significantly improves the visual perception of packaging, providing a competitive edge in the market, he said.

Flexure Print N Pack was established by Ketu S Shah and has been using flexographic printing technology since the very beginning. Ketu Shah has been in the flexible packaging industry for more than four decades. He was earlier involved in the trade business of flexible packaging materials for more than two decades.

Flexure Print N Pack now prints and supplies flexible packaging material to customers in segments such as bakery, dairy, Indian snacks, spices, frozen foods, pet foods, agricultural products, textiles, beauty care, and bio-care in India and across the world.

KetuShah, who is the chairman, looks after the overall activities of Flexure Print N Pack while his elder son, Jainam K Shah, looks after the engineering and manufacturing operations. His younger son, Rohan K Shah, who is the director of sales, heads the sales and business development division of the 20-year-old company.

Bullish about the future of Flexographic printing in India

Commenting on the future of flexographic printing in India, Jainam Shah expressed optimism, noting a gradual shift from rotogravure to flexographic printing technology. He emphasized the suitability of flexography for short and mid-quantity print runs and highlighted the need for press room personnel to deliver superior results to compete with rotogravure technology. For large quantity print runs and printing with challenging as well as environmentally friendly substrates, Flexographic printing process dominates other printing technologies, he added.

“Short-run jobs are well suited to flexography. However, since rotogravure has a better market share and high-quality results, this market is mostly with rotogravure. To shift this market to flexography, at least flexographic printing companies need to produce on par or better results than rotogravure and what we have done is a step towards that,” Shah said.

Echaar CI flexo press was commissioned last year

Last year, Flexure Print N Pack wrapped up a multi-crore investment drive involving new machinery and a second unit adjacent to its existing manufacturing facility. The company also commissioned its first CI flexographic printing press. Till then, Flexure Print N Pack had been using stack-type Flexographic Printing presses.

The company has set up a second unit which is now connected to the first one. The first unit houses multiple stack-type flexographic presses, slitting machines, lamination machines, and multiple converting machines.

The second unit was established in the previous year and houses the new fully loaded 300 MPM speed; 8-color FLEXOSMART HR300 Gearless Servo Printing press, photopolymer printing plate mounting machine, photopolymer printing plate cleaning and anilox sleeve cleaning machine in the press room facility.

The second unit also has a solvent-based lamination machine with a register coating facility, solvent-free lamination machine, stand up+ zipper+ quad seal with register insert gusset pouch-making machine and high-speed cantilever differential slitter rewinder machine. The combined area of the first and second units is about 40,000 square feet in total.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now