GEA has recently developed a new, transcritical CO2 technology especially for use on seagoing vessels. The company has signed a contract last year with P&O Cruises – world’s largest commercial cruise ship operator, for its new transcritical CO2 refrigeration technology. The said environmentally friendly refrigeration technology has already been installed onboard the Arcadia, a 2,000-passenger ship from P&O Cruises, where it provides energy-efficient refrigeration for all the ship’s food and beverage refrigeration systems. Further orders for its transcritical CO2 refrigeration technology have now been received by GEA for two new cruise ships to be built in China and for a Dutch fishing trawler, the second largest in the world says press statement.

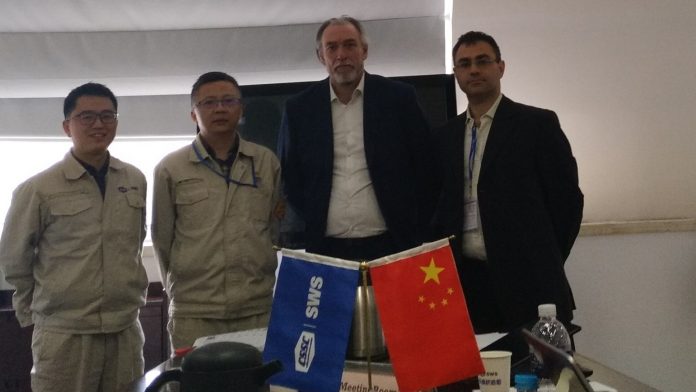

According to the company, in May 2019, GEA signed a contract for transcritical CO2 refrigeration technology with Shanghai Waigaoqiao Shipbuilding (SWS), China. The agreement between GEA and SWS provides for the supply of energy-efficient refrigeration and freezing for all food and beverage refrigeration equipment on two cruise ships. The first 133,500 GT ship will be delivered in 2023.

Marc Prinsen, head of Application Center Utilities Marine at GEA said, “The cruise market is booming worldwide. In China alone, growth to 4.5 million Chinese cruise passengers is forecast by 2020. This will be the first newly built cruise ship to be equipped with this type of sustainable technology. This is a really important reference project and we believe it will lead to a major spin-off.”

Equipping the world’s second-largest trawler

Cooling systems are the backbone of every fishing ship, especially when it comes to fishing trawlers. And, of course, trawlers also have to comply with global environmental agreements. GEA signed a contract with UAB Atlantic High Sea Fishing Company which is a 100 % daughter company of GEA’s long-lasting Dutch customer Parlevliet & van der Plas. According to this contract, GEA equipped the FV Margiris with an NH3/CO2 cascade plant. The trawler is the second largest of its kind in the world.

Marc Prinsen added, “At GEA, we are once again one of the pioneers in this technology. We are convinced that with our transcritical CO2 technology we will win further orders and customers”. And he explains “In recent years, many investments have been made in fishing trawlers, especially in Russia. Companies are building fewer but larger vessels, and many are in a situation where they have to renew their vessels because they are reaching the end of their life cycle. These new trawlers must meet environmental standards. We would like to help with GEA solutions.”

GEA’s transcritical CO2 solution

The use of environmentally friendly, sustainable cooling systems with environmentally friendly CO2 is relatively new in the marine business as it is difficult to develop flexible CO2 cooling systems that can be safely installed in the confined and mobile environments of seagoing vessels. Cooling systems using environmentally friendly CO2 as an alternative refrigerant to chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) are already in use in the retail sector. GEA’s solutions claimed to be tailored to almost any available space on board and are designed to operate safely, robustly and reliably even in difficult weather conditions.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now