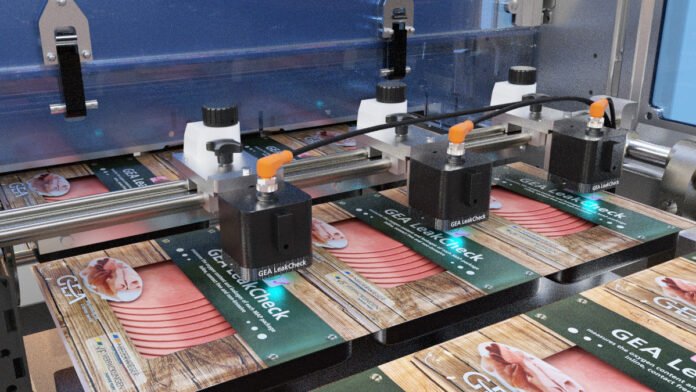

With LeakCheck, Gea is launching a new in-line measurement system capable of checking the seal and package integrity on all forms of modified atmosphere packs (MAP) contactless. This guarantees the protective function and the quality of the food packaging for goods in perfect condition, says the company.

Consumers want fresh, hygienically packaged food while retailers want long-lasting products that look attractive. Positioned at the start of the supply chain, food manufacturers must provide solutions that meet all hygiene and quality standards. Meeting these demands while at the same time boosting productivity calls for end-to-end process monitoring automation.

Based on Gea’s OxyCheck quality control system, the LeakCheck now uses an in-line process on the Gea thermoformer to test the seal and package integrity on each package.

The test procedure comprises three steps. First, the residual oxygen content in each package is measured with a fluorescent sensor spot printed on the inside of the top film. Optical sensors mounted on the thermoformer project light onto the sensor spot, gauging the wavelength of the light emitted by the dye to determine the oxygen content accurately. This step alone, according to Gea, significantly reduces the risk of defective packaging with excessively high residual oxygen levels.

Next, packages are subjected to overpressure and under pressure in a stress unit before a second contactless measurement is taken. If the new result differs from the first, the package seal is broken. Using the Gea CombiPick, the leaky package is automatically detected and accurately removed on exiting the packaging machine. This method ensures that even the smallest leaks are detected.

Residual oxygen content and seal integrity

To boost food processing productivity, the industry is increasingly focusing on automation. The aim is to achieve a consistent or even enhanced product quality. According to the press release, due to Gea LeakCheck, the two key factors for ensuring food safety – residual oxygen content and seal integrity – can now be continuously recorded and monitored on an end-to-end basis. In addition, Gea claims that process errors are rapidly detected, and the delivery of faulty packaging is virtually zero.

In summary, Volker Sassmannshausen, senior product manager- Thermoforming Packaging Systems at Gea, again makes it emphatically clear, saying, “With the Gea LeakCheck, all units leaving the packaging machine are tested non-invasively. Since the measuring techniques are non-invasive, neither the packaging material nor the contents are wasted. Besides efficiency and sustainability, the upshot is that practically no defective packaging reaches the market.”

Both systems are offered as optional extras with Gea’s PowerPak or PowerPak PLUS thermoformers.

Gea is one of the largest suppliers for the food processing industry and of related industries. The international technology group specializes in machinery and plants as well as process technology and components. Gea offers sustainable energy solutions for sophisticated production processes in various end-user markets and offers a comprehensive service portfolio. The group generates around 70% of its revenue in the food and beverage sector that enjoys long-term sustainable growth.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now