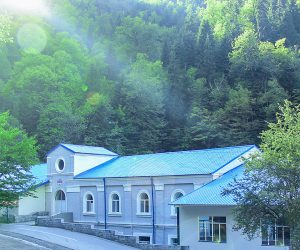

Another APF-6004 blow molder has reached Sakartvelo (or Georgia), one of the world’s most ecologically diverse places in the world. Sairme Mineral Waters brought the equipment and installed it in the very heart of one of the biggest homonymous resorts in Europe. It is the land of high mountains with picturesque slopes, the land of mountainous rivers and springs.

Overview

Sairme waters have been known since 1893. In Georgian, the name “Sairme” means “the place where deer dwell.” The bottling plant is located in Western Georgia, 950 m above sea level, in the Sairme resort. Modern Sairme Mineral Waters plant was inaugurated in 2006.

Since then, its spring water, containing a unique, balanced concentration of calcium, magnesium, and sodium, has become available far beyond the resort’s borders. Now you can enjoy it in 17 countries of the world!

This is where packaging comes in. The role of the bottle increases with distance. The more kilometers are between the Sairme plant and the final destination of water, the less vulnerable the container should be. Thus, the company fills its products both in glass and PET bottles. Equipment developed by PET Technologies helps to produce the latter.

Benefits

Not long ago, Sairme Mineral Waters expanded its manufacturing facilities and installed an APF-6004 blow molder. What benefits did the company have?

- “turnkey solution” from PET bottles design to start-up and commissioning of APF-6004 blow molder, training of customer’s technical staff and after-sales service;

- Mold quick-change permits the production of the whole range of bottles from 500 ml to 2 L with one blow molder. In just 20 minutes, the company switches from one format to another!

- No downtime: the schedule of maintenance permits to follow it during shift change or days off, electric and pneumatic components of European, US, and Japanese brands increase reliability.

Let’s look at this ergonomic bottle! It is transparent with a tint of green that highlights its natural origin, life, and energy. Bottle shoulders resemble a drop that forms high in the mountains, in a Riverhead. This is where the company collects water. Narrowing in the center of the bottle looks as if it were a swift-running mountainous river.

The applied technology plays a crucial role in the manufacturing of this bottle. Intense preform heating and simultaneous air-cooling guarantee uniform temperature distribution between the inner and outer wall.

8-zone heating and availability to move the lamps in any position guarantee that the most complex bottle will meet the predetermined characteristics, even if it is 100% rPET!

The partnership between PET Technologies and Sairme Mineral Waters is always fruitful

A quote says that great partnerships thrive because the people need each other. The same happens with the companies. This project is proof.

The roots of fruitful cooperation between PET Technologies and Sairme Mineral Waters go back to the year 2015. Then the bottling company looked for a reliable supplier of blow molds for 6 – 10 L bottles. PET Technologies attracted attention due to the manufacturing facilities equipped with 4-, 5-axis machining centers and guaranteed delivery terms. Not to mention experience.

The first touch turned out to be successful.

In 2017 we launched the second project together. It was also about blow molds for up to 2 L bottles that Sairme Mineral Waters installed in an automatic PET SBM machine of European brand. They perfectly matched the equipment.

The second touch also turned out to be successful.

It was in 2019 when we reached the peak. Sairme Mineral Waters chose PET Technologies as a supplier of SBM machines. The bottling company was looking for alternatives instead of the blow molding equipment for small bottles that they had.

Previous successful projects for 500 ml, 1.5 L, and 2.0 L molds, carried out in 2017, were a strong point in favor of PET Technologies. Moreover, we developed these bottles’ designs together, taking into account the nature of the blowing process. Thus, Sairme Mineral Waters obtained both attractive and functional PET bottles.

The third touch, the installation of the APF-6004 blow molder, also turned out to be successful. Now we continue cooperation and work together on new projects!

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now