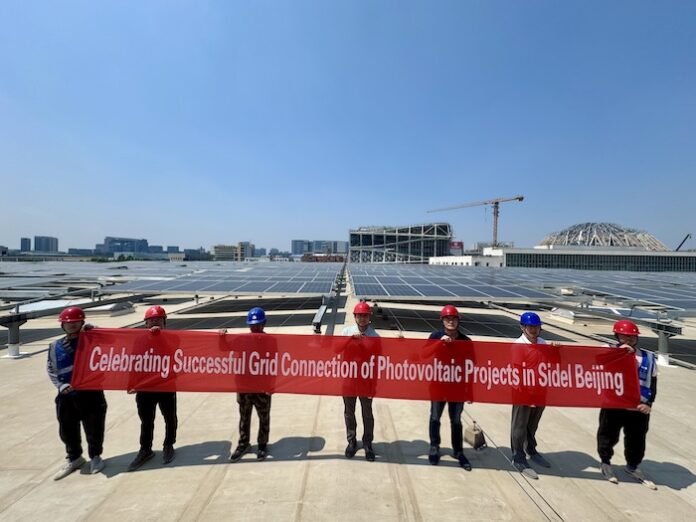

Sidel’s Beijing Plant’s rooftop solar photovoltaic (PV) system has now achieved full grid connection. Thousands of PV panels now form a blue armor-like array across the facility, gleaming under the sunlight. This milestone green energy project injects new momentum into Sidel’s sustainable operations, marking a solid step forward in the company’s decarbonisation journey and setting a new benchmark for green transformation in the industry.

With an installed capacity of 2.1 MW, Sidel Beijing’s solar system is expected to generate 4,394,700 kWh annually – meeting 60% of the plant’s daily operational electricity needs and reducing CO₂ emissions by 2,452 tons per year.

Through the innovative ‘self-consumption with surplus feed-in’ model, 35% of the clean energy generated will be fed back into the municipal grid via smart power networks after fulfilling on-site demand. This enables optimized allocation and efficient utilization of green energy, transforming every ray of sunlight into sustainable power.

As a signature project to China’s ‘Dual Carbon’ strategy implementation, the installation features industry-leading LONGi Hi-MO7 high-efficiency modules with 615W panel power and a top-tier conversion efficiency of 23.1%.

Multi-pronged approach

Since establishing operations in Beijing in 2008, Sidel Beijing Plant has embedded sustainability into its core strategy. Continuous environmental investments and innovations culminated in 2025 certifications including ISO 50001:2018 Energy Management System; ISO 14064-1:2018 Zero Carbon Factory; and GB/T 39257-2020 / GB/T 33635-2017 5-Star Green Supply Chain Management.

As a Beijing-certified Green Factory, Sidel’s environmental efforts go far beyond solar energy, encompassing an intelligent Energy Management System (EMS) and Building Automation System (BAS) for precise energy control; a retrofit program for equipment frequency conversion to reduce consumption; low-temperature distillation technology to minimize effluent from acid-wash passivation; continuous optimization of water recycling systems saving hundreds of tonnes annually; upgraded lighting that cuts power use while improving employee comfort; and on-site EV charging stations to promote greener commuting and lower carbon footprints.

Global green commitment, local implementation

Environmental stewardship remains a Sidel a core value, developing innovative solutions to reduce its footprint. The Group has an ambitious target (73% reduction in Scope 1 & 2 emissions versus 2019 baseline) and has already achieved 64% of reduction in 2024. Since 2022, all Sidel plants globally operate on 100% renewable energy, with the Beijing solar project being a tangible manifestation of this commitment.

“Building a beautiful Earth requires concrete corporate action. This PV system not only slashes our operational carbon footprint but demonstrates Sidel’s unwavering commitment to green manufacturing. We will continue exploring innovative technologies to advance sustainable industry development,” comments Li Yonghon, director, Sidel Beijing Plant.

Standing beneath the solar panel canopy, we see not just clean energy flowing through these silent sunlight harvesters, but Sidel’s resolute journey toward sustainability. Future plans include exploring energy storage solutions and smart energy management to transform the plant into an urban green energy hub.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now