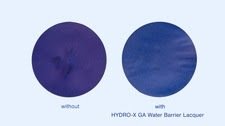

hubergroup Print Solutions is launching a barrier coating that protects against water. It is particularly suitable for surface printing in the packaging industry, both in the food and non-food sectors. By using a revised formulation of the binding agents for the water-based coating, there is no longer any need for PE film lamination as a water barrier. Paper packaging with a barrier coating can be recycled in the already well-established paper recycling system. Changing from conventional packaging to pure paper packaging with a barrier coating is a cost-effective and more environmentally friendly option. The HYDRO-X GA water barrier coating is now available worldwide.

Significant process optimization

Dr Christian Schirrmacher, Global project manager water-based inks from hubergroup Print Solutions, was clearly delighted about the product launch, “We are constantly working to further develop our portfolio. In particular, we focus on the benefits for our customers and the sustainability aspect. With the HYDRO-X GA water barrier coating, as a team, we have achieved another milestone.” He adds, “The aim is to enable our customers to produce more environmentally friendly packaging solutions.”

By using the HYDRO-X GA water barrier coating, it is possible to change from laminate structures to mono-material paper. For this step, only one more available inking unit is needed in order to apply the coating. It has the following advantages:

- Significantly improved recyclability because a well-established recycling system for pure paper packaging already exists.

- The range of applications for pure paper packaging is increased to include sectors that were previously reliant on PE/paper packaging.

- Lower material costs thanks to savings on plastic films, which are now replaced by the coating.

- Reduced processing times because polyethene (PE) lamination or extrusion coating is no longer required, resulting in one less step in the process.

- In a full-cost analysis, the finished product results in lower costs for a sufficient technical barrier effect.

Optimal product protection

The coating provides a highly water-repellent surface, thereby increasing the shelf life of the product. The barrier coating is particularly suitable for use in the packaging industry, specifically for packaging moisture-sensitive foodstuffs such as sugar, flour, and dry animal food. This protective coating prevents unnecessary food waste. It is also suitable for applications in the non-food sector, for example, cement packaging and secondary packaging for copy paper. The HYDRO-X GA water barrier coating is suitable for both coated and uncoated paper.

Successful printing results

Following successful results from laboratory tests, in spring 2020 hubergroup also began testing the coating in a real-world environment together with a customer. This involved print testing on different machines. Dr Schirrmacher explains, “The results were so impressive that we immediately received an order from our customer. They were particularly impressed by the elimination of a step in the production process.”

With the launch of the HYDRO-X GA water barrier coating, the printing ink manufacturer is expanding their water-based portfolio. In doing so, hubergroup continues to pursue their integrated approach to sustainability. Dr Lutz Frischmann, global product director Flexible Packaging, sees that the packaging industry is undergoing major change. He recognizes a clear trend towards mono-materials and therefore towards barrier coatings, “At present, we are working intensively to develop and manufacture additional protective coatings, such as an oxygen barrier coating. Due to the sustainability aspect, we see big potential in these product groups.” More products are expected to be launched throughout the year.

hubergroup is a family business based in southern Germany with a 255-year history. Print Solutions division produces and sells printing inks and printing aids for packaging printing and commercial printing. The security inks segment for international banknote and identity document producers is covered by the subsidiary Gleitsmann Security-Inks. Chemicals Division markets raw materials such as pigments, resins, and additives produced in India.

The company has always been focused on customer success. That is why hubergroup works on innovative solutions, technologies, and services every day in order to optimize the value creation in the printing and chemistry industry and to allow their customers to achieve first-class results. In 2020, hubergroup generated an annual turnover of about EUR 620 million and employs approximately 3,500 employees worldwide in over 30 countries.

Smart Packaging Solutions Virtual Congress -19 March 2021

The Smart Packaging Solutions for India and South Asia Virtual Congress on 19 March focuses on food and pharma supply chains, brand security, and sustainability. Organized jointly by IPPStar and the AIPIA, the virtual congress’s topics include brand authentication, condition monitoring, and active and intelligent packaging that contributes to the safe delivery of authenticated products leading to safety, security, and customer engagement. Please look at the agenda of the conference here, and for registration, please click here. You can also email Ruchi at conference@ippgroup.in or Umesh at subscription@ippgroup.in. Call us in Noida at 120-4546988 or 4326053 – Umesh at Xtension 30; Ruchi at Xtension 33; Gaurav at Xtension 23; and Mohit at Xtension 25.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now