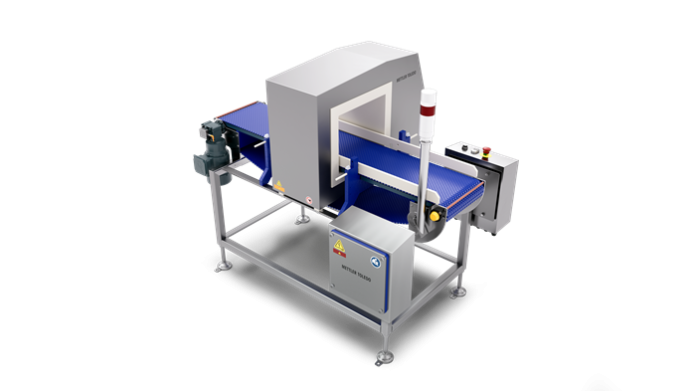

Mettler-Toledo Product Inspection, a global leader in product inspection solutions, has announced the launch of the EC Series conveyors designed to meet the product quality control needs for small to mid-sized food manufacturers.

The EC Series conveyors integrate with the M30 R-Series metal detectors, to offer a reliable inspection solution at an affordable price point for small and medium-sized packaged products in standard production environments. The integrated metal detection solutions are ideal for inspecting a wide range of both wet and dry applications, including meat, bakery and confectionery, ready meals and snack foods.

The simplified EC Series conveyor specifications include a range of options to suit production line integration needs while still meeting BRCGS requirements. Standard components are specified for reliability and ease of maintenance, facilitating maximum uptime and productivity. For example, the modular belt design and streamlined features enables easier cleaning – complemented by an ingress protection IP65 rating – quick servicing, and reduced operator time. Reporting capabilities include OPC UA, USB and connectivity to Mettler-Toledo ProdXTM software for enhanced data management and traceability.

The new conveyors are the result of the commitment by Mettler-Toledo to respond to market demands by providing innovative solutions for customers. By listening to the needs of small and mid-sized manufacturers, the development of the new conveyors meets both budget and regulatory compliance needs at a time when combatting rising costs matters the most.

“An EC Series conveyor coupled with an M30 R-Series metal detector is the perfect detection solution for small to mid-sized businesses seeking affordable quality and compliance,” said Ben Pimblett, head of market management at Mettler-Toledo. “Designed with simplicity and ease of use in mind, our new conveyors suit various production needs while providing maximum uptime due to reduced cleaning and maintenance time.”

The EC Series is compatible with three of the M30 R-Series metal detector models, which identify a range of metals, both magnetic and non-magnetic including all ferrous, non-ferrous, stainless steel and aluminium, matched to different production and compliance needs, and budget considerations.

M31R StandardLine – entry-level versatile and reliable inspection in all food segments; high frequency, tuned technology with eDrive that delivers up to 10% spherical sensitivity improvement over legacy models.

M33R PlusLine – enhanced performance with very high frequency tuned technology and eDrive to deliver an up to 20% improvement in spherical sensitivity performance, ideal for dry applications such as cereal bars, dry pasta, confectionery and snacks.

M34R PlusLine – enhanced performance using Dual-Simultaneous Frequency and Product Signal Suppression technology to improve spherical sensitivity performance by up to 25% and reduce false rejects in wet or conductive applications; tailored to wet, challenging and conductive applications such as meat, poultry, seafood, dairy, products with high salt content and those packed in metallized film.

The EC Series conveyors are available within short lead times and at a cost-effective price point, making it an ideal choice for manufacturers looking to combat rising manufacturing costs quickly.

In addition to the EC Series conveyors, Mettler-Toledo also offers the GC Series conveyors, suitable for larger products and high-volume production environments. Both conveyors can be fully integrated with the M30 R-Series metal detectors, which are designed, supplied and serviced by Mettler-Toledo, providing customers with a single point of contact and a seamless experience from purchase to maintenance.

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now