Kanchan Metals, a leading and pioneer company offering food processing machines, has recently introduced various conveyor belts, especially for the food industry. Considering the market scenario and demand, Kanchan Metals decided to launch new conveyor belts in the food processing segment.

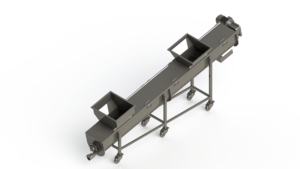

They have introduced these machines under four major categories like snack food application conveyors, frozen food application conveyors, bakery and confectionary conveyors, and packing section conveyors. Within these four categories, there are different types of conveyor belts like wire mesh belts, positive drive belt with flights or scoop for snack food application, spiral freezer in feed and down take conveyors and spiral conveyor for frozen food, non-stick belt dough ball and automatic belt tracking system conveyor for bakery and confectionary, lastly bucket elevator and horizontal Incline conveyor for packing section.

According to the company, these conveyors have a wide range of application-based design and specialized belt selection, considering the most critical aspects like the nature and stage of the product. The conveyor’s design has a modular construction that offers hygiene and product safety throughout the conveying process.

Raghav Gupta, director, Kanchan Metals, said, “We are delighted to announce the launch of our modern and advanced conveying solutions in the snack food sector in India. We are offering best in class conveying solutions with a variety of belts such as Stainless-steel mesh, PU, PVC and modular type. We also offer bucket elevators to feed products to the packing section. These conveyor belts can easily convey gentle or fragile products and hard products, cartons, and boxes. It also saves a lot of space. Along with that, these conveyor belts can be customized as per the user requirements.”

IndiFoodBev — authentic, impactful and influential

An English-language food and beverage processing and packaging industry B2B platform in print and web, IndiFoodBev is in its third year of publication. It is said that the Indian food and beverage industries represent approximately US$ 900 billion in revenues which implies more than 20% of the country’s GDP. Eliminating the wastage on the farmside can help to deliver more protein to a higher number of the population apart from generating sizable exports. The savings in soil, seeds, water, fertilizer, energy and ultimately food and nutrition could be the most immense contribution that country is poised to make to the moderation of climate change.

To improve your marketing and grow sales to the food and beverage processing and packaging industry, talk to us. Our research and consulting company IppStar [www.ippstar.org] can assess your potential and addressable markets in light of the competition. We can discuss marketing, communication, and sales strategies for market entry and growth.

Suppliers and service providers with a strategy and budget for targeted marketing can discuss using our hybrid print, web, video, and social media channels to create brand recognition linked to market relevance. Our technical writers are ready to meet you and your customers for content.

The second largest producer of fruit and vegetables in the world is continuously expanding processing capacities and delivery systems with appropriate innovative technologies. We cover product and consumer trends, nutrition, processing, research, equipment and packaging from farm to thali. Get our 2025 media kit and recalibrate your role in this dynamic market. Enhance your visibility and relevance to existing markets and turn potential customers into conversations. Ask for a sample copy of our bi-monthly in print or our weekly IndiFoodBev eZine each Wednesday.

For editorial info@ippgroup.in — for advertisement ads1@ippgroup.in and for subscriptions subscription@ippgroup.in

Naresh Khanna – 10 February 2025

Subscribe Now